How To Buy A Men’s Necktie

1. Buy A Necktie That Is The Proper Width

We’ll start with the easy part: getting the right size Men’s neck tie. This will serve you well whether you’re buying handmade Italian imports or off-the-rack at Sears. Fashion has widened and narrowed ties back and forth over the years.

A good necktie is right in the comfortable middle. 3 1/4″ is ideal for most men (the width is measured at the widest point, before the tapered tip if there is one).

If you happen to be built particularly broad you may want a little extra width to keep things proportional, on up to 3 3/4″ or so. Similarly, very slender men can go down to about 2 3/4″ without looking like they’re wearing a “skinny tie.”

Ties without any taper (a somewhat old-fashioned style these days) should be a touch skinnier, around the 2 3/4″ range as well.

To quickly judge width in a store I use the dollar test – since the USD is approximately 6 inches long, fold it in half and you have a 3 inch ruler.

Then you can quickly see approximately what width tie you’re about to buy. My sweet spot for my body build/style requirements is 3.25 inches. Yours may be bigger or smaller depending on taste.

2. Buy A Necktie That Is The Proper Length

Lengths vary from manufacturer to manufacturer but most “regular” ties are around 57″-58″, while “extra-long” or “tall” sizes are closer to 62″-64″.

Shorter styles are either meant for very short men (you have to be pretty far under average to need something shorter than 57″ — most shorter guys can just tie a slightly larger knot to use up length) or else are a vintage style.

Short ties were in vogue for part of the 1940s and again in the 1970s, so you may find ones down in the low 50″ ranges if you scrounge around. The best measure of length, however, is how it falls on your own body. The tip of a properly-tied necktie should reach just past the trouser waist.

The skinny end should reach almost as far, an inch or so shorter at the very most. A skinny end that only comes down halfway makes the tie lack body and sway more, and often pokes out from behind if it isn’t pinned in place.

Taller men may have to buy custom ties, or at least specific “long” sizes to be able to tie a satisfactory knot and still have a long enough tail for balance. Shorter men can tie a larger knot like a half- or even full Windsor to use up extra cloth as needed.

3. Select A Quality Built Necktie – Fabric & Construction

Length and width are easy to judge with a ruler and a few minutes in a dressing room. The real difficulty between buying good ties and buying great ones at a value price lies in your ability to judge the fabric and construction.

The highest quality made ties in the world are made from fine silk. Synthetic fabrics give a similar sheen but none of the rich texture and straight drape of silk.

Check to see if the silk has been cut “on the bias” — across the bolt of cloth — by draping the tie over your hand. If it hangs straight it was cut properly. If it curls and twists to one side or the other it was not cut on the bias, and is not going to hang as neatly.

The texture of the silk is also important. Rough silk that catches on your skin as you slide a hand over it indicates a cheaper product. The fibers are already stiff, and will break and lose their luster quickly. Look for smoothness and flexibility in the surface.

Judging Quality, Handmade Construction

Only the most expensive hand-made ties are still made by folding a single piece of silk over and over on itself. Most get their weight from an interior lining. How that lining is constructed separates the good ties from the great.

The Tie’s Lining – Very fine ties are lined with 100% wool. This is quite expensive and fairly rare,since the fine, lightweight wool cloth is prohibitively costly to manufacture.

Blended wool can still make a fine tie — some manufacturers still mark the fineness of the wool with gold-colored bars on the inner lining, which is a good sign that you’re dealing with a quality maker. Don’t look for it exclusively, however, as many newer ties may have abandoned the gesture.

The Tie’s Bar Tack – What you can still look for on quality ties is the “bar tack.” The name is a little misleading — it’s actually a small horizontal stitch on the back of the tie, right where the wide end splits to form the tip, holding the two sides together. This helps keep the tie’s shape and is often absent on mass-produced ties.

The Tie’s Slip Stitch – If you open the back of a necktie up slightly and see a loose black thread hanging lengthwise down the inside, it’s not a manufacturing defect. That’s the “slip stitch” — an extra stitch made down the center of the tie so that the fabric can shift up and down slightly as you tie it.

Necktie Triple Construction – Neckties are made by joining multiple lengths of cloth together (remember how they’re made from cloth cut across the bolt rather than down it).

Good construction usually uses three panels, so you should be able to feel two different seams if you press your finger into the fabric and run it along the length of the tie.

Cheaper ties often use two lengths instead of three. The third panel sits neatly around the neck, which helps the ends of the tie hang more smoothly. Any tie where the seams are visible on the outside is, of course, poorly-made and not worth considering.

Showing 49–72 of 89 results

-

S&W SHLAX&WING Mens Ties Necktie Pack Emerald Green Classic Size 57.5″

$9.99 Learn More -

S&W SHLAX&WING Mens Ties Ripple Blue Multicolored Silk Green 57.5 inches

$9.99 Learn More -

S&W SHLAX&WING Mens Ties Set Gray Blue Striped Grooms Formal Neckties Skinny Necktie with Pocket Square Set

$11.99 Learn More -

S&W SHLAX&WING Mens Ties Silk Necktie Dark Blue Navy Red Stripe Extra Long Size 63″

$9.99 Learn More -

S&W SHLAX&WING Mens Ties Silk Neckties Yellow Mustard Paisley Extra Long Size 63″

$9.99 Learn More -

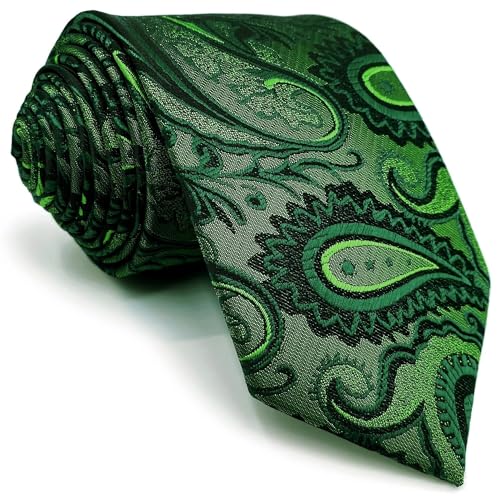

S&W SHLAX&WING Neck Tie Sets for Men Matching Necktie Dark Green Paisley Classic Size 57.5″

$9.99 Learn More -

S&W SHLAX&WING Necktie Set Striped Mens Necktie Golden Yellow Royal Blue Navy Stripes Tie with Pocket Square

$11.99 Learn More -

S&W SHLAX&WING Neckties for Men Blue with Red White Stripes Classic Size Ties Set for Suits

$11.99 Learn More -

S&W SHLAX&WING Neckties for Men Dotty Purple with Blue Dots Tie Set with Pocket Square Extra Long 63″

$11.99 Learn More -

S&W SHLAX&WING Neckties for Men Orange Blue Neck Tie Set Big and Tall xl Pack

$11.99 Learn More -

S&W SHLAX&WING Neckties for Men Tie Pack Dark Green Paisley Classic Size 57.5″ with Pocket Square

$11.99 Learn More -

S&W SHLAX&WING Neckties Set Solid Blue Navy for Suit Ties Pack Dark Fringe Classic

$11.99 Learn More -

S&W SHLAX&WING New Mens Ties Silver Sky Blue Necktie Extra Long Size

$9.99 Learn More -

S&W SHLAX&WING Silk Ties for Men Groom Necktie Yellow Luxury Extra Long

$9.99 Learn More -

S&W SHLAX&WING Silk Ties for Men Necktie and Hanky Set Slate Blue Dot Skinny Size 2.36″ with Pocket Square

$11.99 Learn More -

S&W SHLAX&WING Slim Tie Mens Necktie Skinny Navy Orange Geometric Silk 2.36 inches

$9.99 Learn More -

S&W SHLAX&WING Solid Color Red Wedding Silk Neckties for Men Classic Tie 57.5 inches

$9.99 Learn More -

S&W SHLAX&WING Tie for Men Grooms Neckties Blue Navy Paisley Extra Long Necktie

$9.99 Learn More -

S&W SHLAX&WING Tie Sets for Men Dark Gray Neck Tie Brown Striped Extra Long Necktie

$9.99 Learn More -

S&W SHLAX&WING Tie Sets for Men Neckties Blue and Gold Paisley Extra Long Size 63″

$9.99 Learn More -

S&W SHLAX&WING Tie Sets for Men Neckties Blue Orange Check Classic Size 57.5″

$9.99 Learn More -

S&W SHLAX&WING Tie Sets for Men Silk Grooms Neckties Gold Floral Blue Classic Size Necktie

$9.99 Learn More -

S&W SHLAX&WING Tie Sets for Men Wedding Necktie Red Burgundy Dot Extra Long Size 63″

$9.99 Learn More -

S&W SHLAX&WING Ties for Men Blue Navy Necktie Set Paisley Classic Size Necktie with Pocket Square Set

$11.99 Learn More